-

Power Supply Equipment Market for Water Electrolysis 2023-2032: Unveiling Growth Opportunities and Competitor DynamicsAdvanced Materials and Chemicals 2025. 1. 24. 15:36

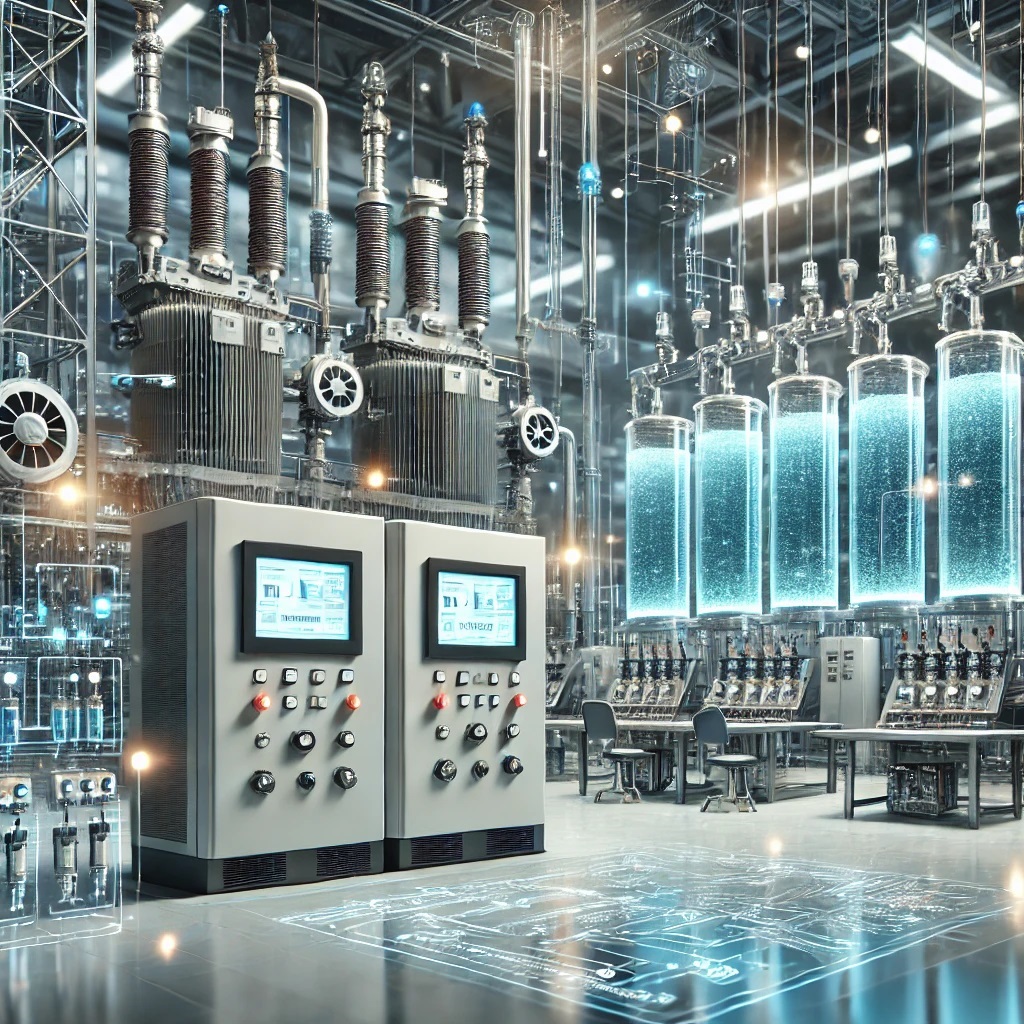

Power Supply Equipment Market for Water Electrolysis The Power Supply Equipment Market for Water Electrolysis is a cornerstone in the global shift toward clean energy. As industries adopt hydrogen-based solutions, power supply equipment for electrolysis is becoming essential for efficient and scalable hydrogen production.

The power supply equipment market for water electrolysis was valued at $331.5 million in 2022, and it is expected to grow at a CAGR of 33.27% and reach $5,714.8 million by 2032. This Market is predicted to expand due to supportive government initiatives, tight net zero standards, and increased demand for hydrogen fuel cell vehicles, green ammonia, green methanol, and other applications.

Market Growth

The growing demand for green hydrogen, fueled by global decarbonization goals, is accelerating the adoption of advanced power supply equipment. This shift is driven by the need for sustainable energy solutions in industries such as steel and chemical manufacturing. Innovations in power supply technologies, emphasizing efficiency, durability, and cost-effectiveness, are reshaping the market, ensuring reliable and scalable solutions to support the hydrogen economy's expanding role in achieving net-zero emissions.

Key Technologies

Technological advancements redefining the Electrolysis Power Supply Market include:

- DC Power Supplies: DC power supply allow precise voltage and current regulation, resulting in stable and efficient hydrogen production during electrolysis. By providing continuous power, these supplies optimize the electrochemical process, eliminate energy loss, and improve overall system reliability, making them critical for scalable and sustainable hydrogen generation.

- Energy Storage Integration: Energy storage integration stabilizes power input for electrolysis by storing renewable energy sources like solar and wind. This technique provides continuous hydrogen production despite fluctuations in energy supply, improving system efficiency and allowing for the smooth integration of renewable resources into hydrogen producing processes.

- High-efficiency converters: High-efficiency converters maximize energy use by reducing power loss during the electrolysis process. These sophisticated converters lower operational costs and increase hydrogen production scalability, making them an essential component in attaining cost-effective and sustainable green hydrogen generation for industrial applications.

Request A Detailed Sample on the Power Supply Equipment Market!

Demand Drivers

The demand for Electrolysis Power Supply is rising due to:

- Global Green Energy Policies: Governments throughout the world are promoting hydrogen as a clean energy source, enacting supportive laws and incentives to encourage its adoption. This transformation is creating a robust market for electrolysis systems, allowing companies to switch to more sustainable energy options and fulfill ambitious global decarbonization targets.

- Industrial decarbonization: Industries like steel and chemicals are increasingly using green hydrogen to replace traditional fossil fuels. This change is increasing demand for electrolysis power supplies, which are critical for creating hydrogen on a large scale and supporting industrial initiatives to cut carbon emissions while preserving operating efficiency.

- Technological advancements: Innovations in electrolysis power supply technologies are increasing efficiency and lowering costs, making green hydrogen more competitive. These developments include high-efficiency converters and improved control systems, which enable scale hydrogen generation and hasten the global transition to sustainable energy options.

Rectifier Segment Driving Growth in Electrolysis Power Supply Market

The rectifier segment is expected to grow significantly due to its critical role in water electrolysis plants. IGBT rectifiers, in particular, are gaining traction for their fast response times, high efficiency, and minimized energy losses. Transformers support voltage optimization, especially when renewable energy powers electrolysis systems.

Key Market Players

Leading companies shaping the Electrolysis Power Supply Market

Private Companies

- AEG Power Solutions B.V.

- Ingeteam

- Comeca Group

- TMEIC

- Prodrive Technologies

- FRIEM SPA

- Statcon Energiaa Pvt. Ltd.

- Green Power Co., Ltd.

- KraftPowercon

- Mak Plus Power Systems

- MUNK GmbH

- Liyuan Rectifier Group

Public Companies

- General Electric

- Sensata Technologies, Inc.

- Ador Powertron Ltd

- Nidec Industrial Solutions

- Danfoss Drives

- ABB

- American Superconductor

- SMA Solar Technology AG

Conclusion

The Electrolysis Power Supply Market is essential for achieving global clean energy targets. With advancements in power electronics and green hydrogen policies, this market is set to flourish. Companies that innovate in this space will spearhead the clean energy revolution.

BIS Research, recognized as a best market research company, provides premium market intelligence reports on deep technologies poised to cause significant market disruption in the coming years.

At BIS Research, we focus exclusively on technologies related to precision medicine, medical devices, diagnostics, life sciences, artificial intelligence (AI), machine learning (ML), Internet of Things (IoT), big data analysis, blockchain technology, 3D printing, advanced materials and chemicals, agriculture and FoodTech, mobility, robotics and UAVs, and aerospace and defense, among others.

'Advanced Materials and Chemicals' 카테고리의 다른 글